Making a double top

Why a double top …

and double sides!

More sound and dynamics through an ultra light and vibrant top.

Some history and

Some more technique

A double-top classical or acoustic guitar (also called “composite top” or “sandwich top” is a type of guitar that features a guitar top made of two layers of tonewood (same kind or different) separated by material like Nomex ( a kevlar polymer, manufactured in a honeycomb pattern, originally developed for the aviation industry), balsa wood or other (sometimes being a secret of the guitarmaker) this way that, there are many empty (air filled) spaces. Such guitars were pioneered by German Luthiers Gernot Wagner and Mathias Damman.

Double-top is not as thin as lattice braced top and behaves, acoustically speaking, much more like a traditional solid top guitar.

The purpose of this concept is to increase the amount of sound energy that is emitted from the guitar’s soundboard, without increasing the weight of the guitar. This results in a guitar that has a louder, more responsive sound and improved projection. Additionally, the use of a double top can also help to improve the overall stability of the guitar, as the additional layer of material helps to stiffen the soundboard and reduce the risk of warping or cracking.

Many great concertguitarists choose nowadays for double top guitars: Irina Kulikova, Jason Vieaux, Bill Kanengiser, Duo Melis

Technique

the making of …

outer top

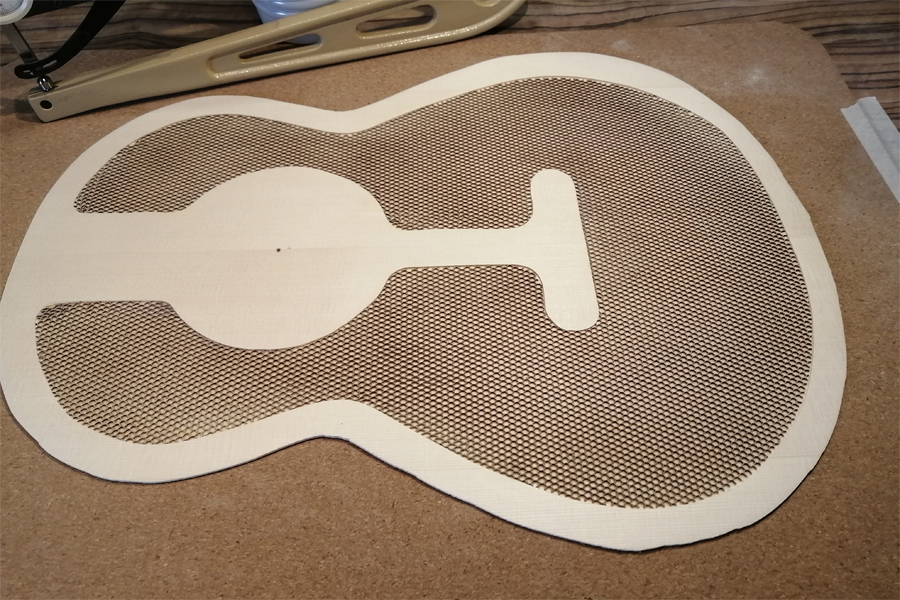

With a mould we router a part of a traditional 3mm top back to 1mm. Some parts we keep solid for constructionreasons.

in between

We fill the space with 1,5mm Nomex honeycomb material

inner top

After levelling we glue a 1mm inner blade to the composite.

finishing

After sanding all to proportion we have a guitartop that weighs anout 30% less than traditional.